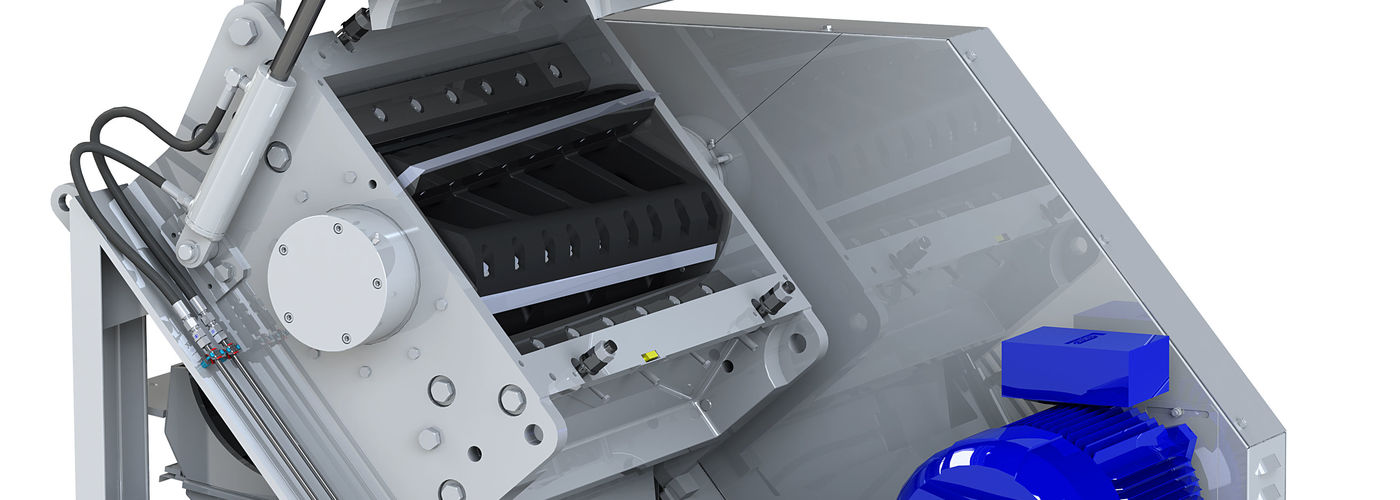

Granulator for bulky feed materials

Hosokawa Alpine, one of the leading suppliers on the sector of process technology and film extrusion, will present the Polymer-Line PL-XS 45/100, a compact granulator for the economic size reduction of large-volume and bulky plastic products at this year's K-Show. Thanks to its special cutting chamber geometry, the granulator has excellent product intake and size reduction properties. "The ingenious cutting chamber design also ensures quiet machine operation, as the result of which the instances of feed product being ejected from the machine are reduced to almost zero", says Jörg Krause, Head of Engineering of the Recycling and Granulators Division of Hosokawa Alpine's process technology business segment.

Recommend article